Precision frame alignment, facilitated by advanced laser tools, is a critical process in automotive workshops ensuring vehicle structures are correctly adjusted after accidents or repairs. This technology offers unprecedented accuracy and efficiency, reducing human error, enhancing consistency, and improving overall service quality. By adopting laser tools, collision repair shops can provide higher-quality work that meets or exceeds factory standards, boosting customer satisfaction and expanding their service offerings.

Shops are transforming their frame alignment services with laser technology, revolutionizing a process once reliant on manual, time-consuming methods. This article explores precision frame alignment, delving into the growing reliance on laser tools for unparalleled accuracy in shop operations. We’ll uncover how laser technology benefits various industries, from automotive to construction, by providing consistent, repeatable results crucial for quality craftsmanship and efficient workflows.

- Understanding Precision Frame Alignment: The Need for Accuracy in Shop Operations

- Laser Technology: A Revolutionary Approach to Frame Alignment Services

- Benefits and Applications of Laser Tools in Achieving Optimal Precision Frame Alignment

Understanding Precision Frame Alignment: The Need for Accuracy in Shop Operations

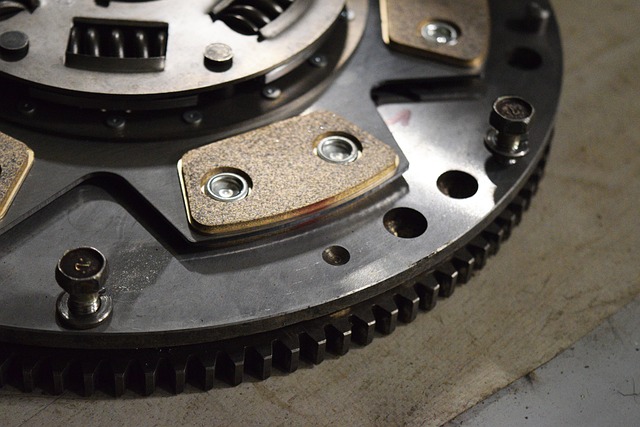

Precision frame alignment is a critical process in automotive workshops, ensuring that vehicle structures are correctly adjusted after accidents or repairs. Accurate frame alignment is vital for several reasons; it guarantees the safety and structural integrity of the vehicle, allowing it to withstand future collisions effectively. Moreover, it plays a significant role in determining the overall quality of car body repair and paintless dent repair services offered by body shops.

In the realm of shop operations, achieving precise frame alignment is essential for maintaining customer satisfaction and ensuring long-lasting vehicle performance. Modern body shop services often utilize advanced laser tools to accomplish this task, enabling technicians to make exact measurements and adjustments. This technology is particularly valuable in complex car body repair scenarios, where minimizing misalignments can significantly impact the final aesthetic and structural results.

Laser Technology: A Revolutionary Approach to Frame Alignment Services

Laser technology has revolutionized precision frame alignment services in the auto industry, offering an unprecedented level of accuracy and efficiency. This innovative approach streamlines the process of correcting vehicle frames that have been damaged due to accidents or wear and tear, ensuring that cars return to their original structural integrity. Unlike traditional methods that may rely on manual measurements and adjustments, laser tools provide precise data and real-time feedback, minimizing human error and maximizing consistency.

Shops leveraging these advanced tools can deliver superior body shop services, including auto body work and tire services, with remarkable speed and accuracy. By investing in laser technology, businesses can enhance their capabilities, cater to a wider range of customers’ needs, and maintain high standards of safety and quality in every repair job undertaken.

Benefits and Applications of Laser Tools in Achieving Optimal Precision Frame Alignment

Laser tools have revolutionized precision frame alignment services in collision repair shops. Their advanced technology offers numerous benefits over traditional methods. By utilizing laser measurements, technicians can achieve unparalleled accuracy, ensuring every component is aligned perfectly. This is particularly crucial in car bodywork, where even slight misalignments can compromise safety and vehicle performance.

The applications of laser tools are extensive within collision repair shops. They enable precise measurement and adjustment of frame panels, ensuring the structural integrity of the vehicle after repairs. Moreover, laser technology aids in aligning doors, hoods, and trunks with meticulous care, resulting in a seamless finish that meets or exceeds factory standards. This level of precision not only enhances the overall appearance of the repaired vehicle but also increases customer satisfaction in collision repair services.

In conclusion, the adoption of laser tools for precision frame alignment services marks a significant advancement in shop operations. This revolutionary approach, highlighted by the benefits and applications discussed, ensures unparalleled accuracy and efficiency. By leveraging laser technology, shops can deliver superior quality outcomes, catering to the demanding needs of modern manufacturing and repair processes. Precision frame alignment is no longer a luxury but an essential practice for maintaining high standards in various industries.